Lighting

Transformation of flat glass

for the public

lighting industry

Our tempered glass not only improves the aesthetics of the lighting unit,

but it also provides superior strength and safety. We produce glass according to

our customers' specifications, from geometric to irregular shapes, with high-precision finishes and

the option of printed customisation. By choosing our glass, you ensure your

products' high optical and quality standards, as well as optimal performance in terms of

durability and reliability.

Display

Transformation of flat glass

for display screens

Our tempered glass is ideal for improving the visual quality and the

robustness of display devices. We produce glass according to customers' specifications

with excellent optical characteristics from anti-reflective surfaces to

high-precision manufacturing ensuring a perfect fit. We offer customisation options including

screen-printing and special treatments, ensuring high resistance and reliable performance.

By choosing our products, you enhance your display with a level of quality that combines

aesthetics, functionality and durability.

Underwater

Transformation of flat glass

for underwater equipment

Our tempered glass for masks and underwater lighting offer

an optimal combination of resistance, clarity and safety. We produce glass according to

our customers' specifications, from standard geometrical shapes to those more complex,

ensuring heightened dimensional accuracy and excellent optical quality.

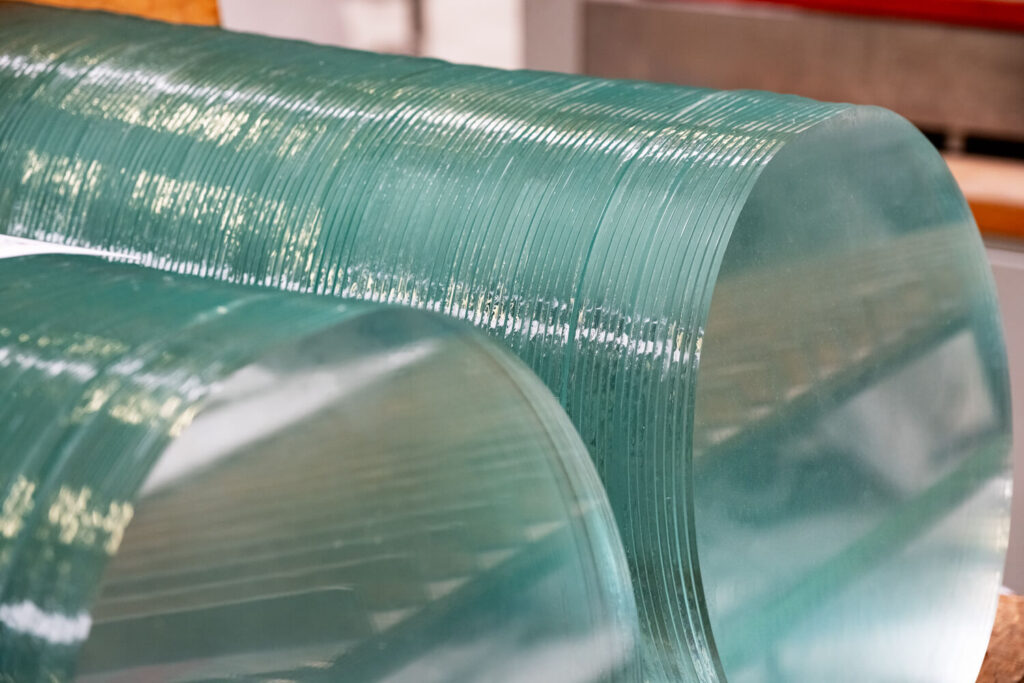

Specialising in flat glass processing, Metalfilms manufactures small-sized tempered glass to order, starting with large panes of various thicknesses.

The process includes cutting, grinding, drilling and screen-printing using ceramic enamels. After these manufacturing phases, our glass is tempered to guarantee mechanical strength, resistance to thermal shocks, and in accordance with UNI EN12150 to ensure the glass is safe in case of breakage .

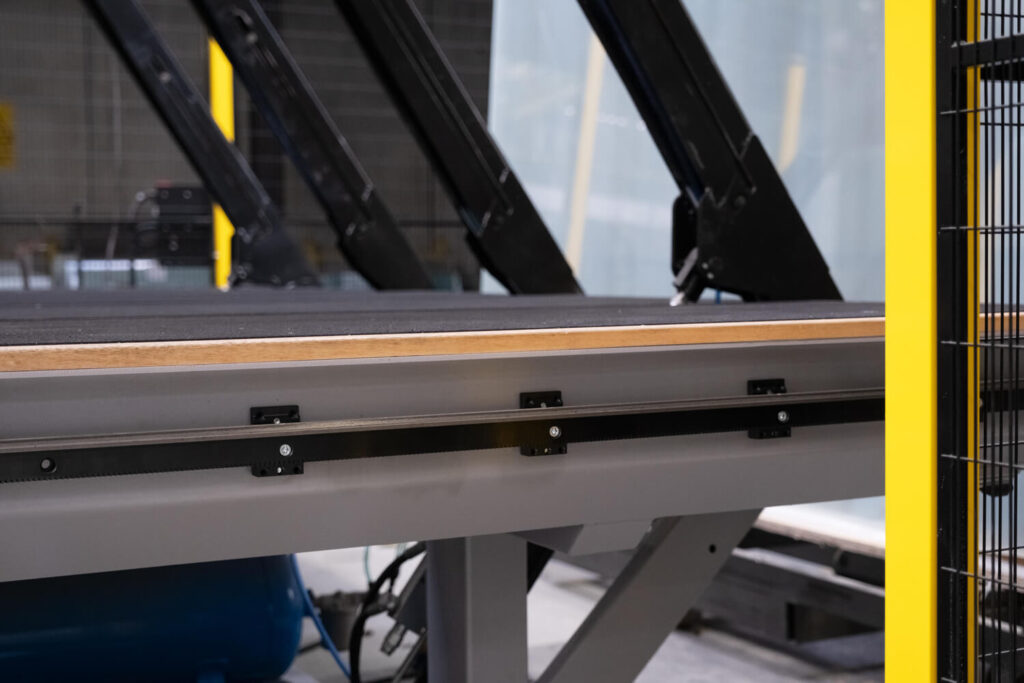

The glass is cut with precision thanks to an automatic cutting table and subsequently the edges are ground to obtain the required finishing.

Gallery

Main Industries

Manufacturing process

The panes of glass are cut with precision thanks to an automatic cutting table and the edges are subsequently ground to obtain the required finish.

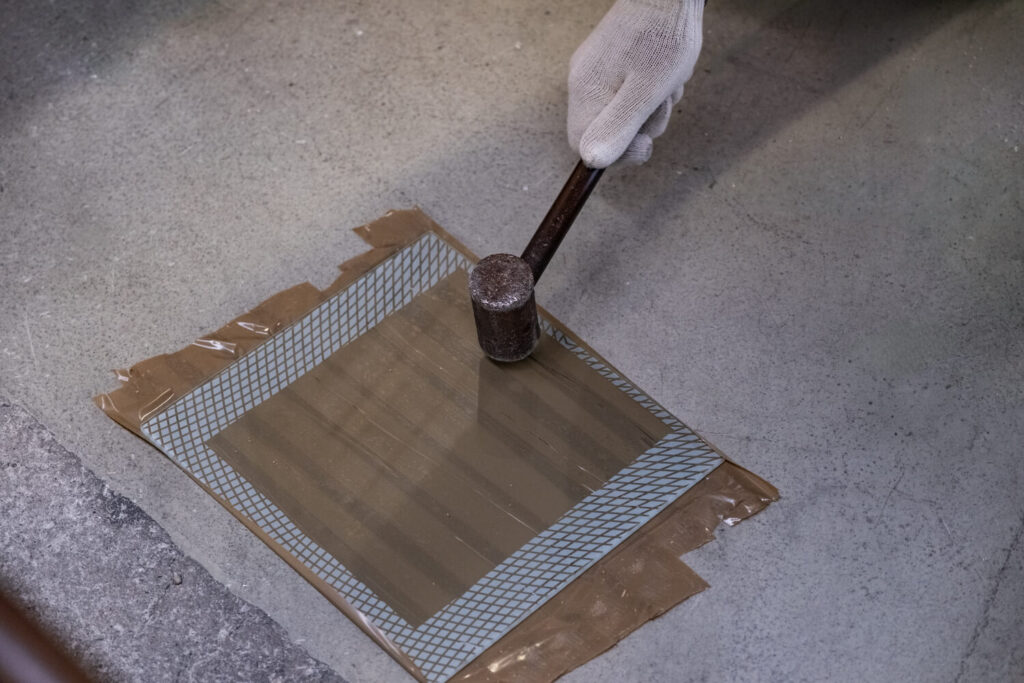

As well as cutting and grinding, Metalfilms also drills and screen-prints for maximum customisation. The last step in the process involves tempering the glass. The glass is brought to around 600°C and then rapidly cooled to guarantee strength and safety. Once tempered, the glass cannot undergo further processing.

Lighting

Display

Underwater Industry

Types of glass

Why choose us?

For Metalfilms, quality means guaranteeing the highest customer satisfaction through rigorous checks and continual improvement of its operations. With more than 40 years of experience, chain of custody and as a certified ISO 9001, ISO 22000 and ISO 45001 company, Metalfilms adopts standard or custom procedures for each phase of the manufacturing process. Each element is checked and registered to ensure high performance and compliance with the required specifications. Quality control is undertaken at the end of each phase of manufacturing by trained operators. Furthermore, spot checks are carried out on each manufactured lot, by the quality control department.